Custom Acrylic Mirror Fabrication

In the production of acrylic mirrors, we produce customized products according to the different requirements from different users. Normal requirements include such as length, width, thickness, shape, and semicircle radius, or diameters and so on, but also include other requirements such as hardness, anti-scratches.

How Acrylic Mirror is Fabricated?

Step 1: Acrylic cutting

Acrylic sheets are cut according to requirements using acrylic-cutting blades, plastic cutter, saber saws, table saws or routers. The use of laser cutting machine for acrylic sheet or acrylic mirror sheet cutting into the desirable shape needs to ensure a certain tolerance range which is less than 0.02mm;

Step 2: Acrylic drilling

This acrylic drilling is an option. When we see the acrylic mirror, it is usually made directly through electroplating and screen printing. It is rare to see the drilling product, but there will be some needs or novel ideas, which can be drilled to reach the desired effect.

Step 3: Acrylic polishing

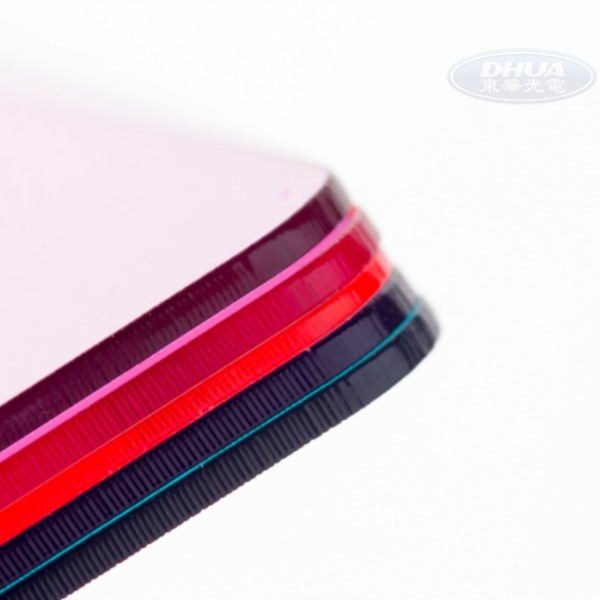

When acrylic sheets are manufactured to acrylic mirror sheets, there is a basic requirement, that is no raw edges around acrylic sheets. Acrylic sheets must be given a glossy finishing at the edges .

Step 4: Acrylic coating

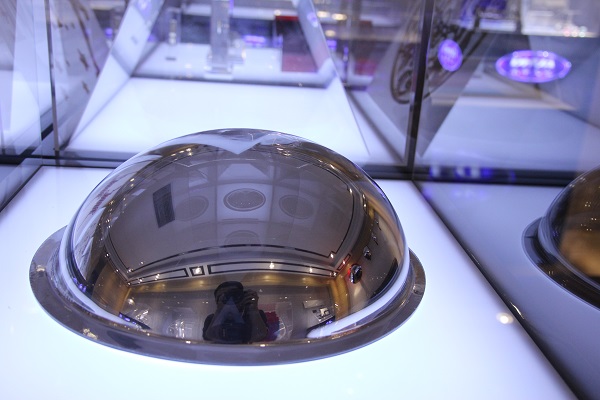

This is the production process of acrylic mirror made of acrylic sheet, usually the way is acrylic mirror electroplating. Mirrorizing is done by the process of vacuum metallizing with aluminum being the primary metal evaporated. In addition, according to the different requirement for the light transmittance of the mirror, different electroplating process can make opaque, semi-transparent acrylic mirror, and the full transparent mirror.

Step 5: Acrylic thermoforming

Some acrylic mirrors are not same as the common acrylic mirrors, most of the acrylic mirror is a PMMA sheet, and some needs to be changed their shape due to some special reasons, at this time we can make the acrylic mirror sheet stop heating and become the shape customer demands by thermoforming technology.

Step 6: Acrylic printing

With the help of methods like spray painting and screen-printing, we can add logo or words and pictures on the acrylic mirror sheet to render desirable colors and decorations.

Post time: Mar-04-2022