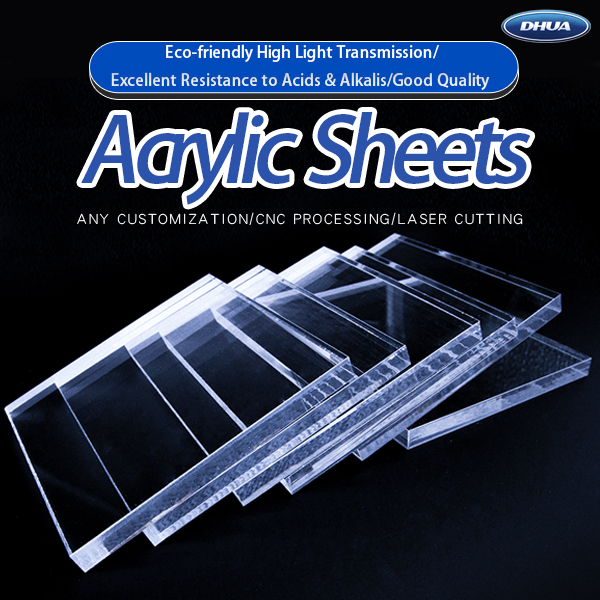

Cheapest place to buy plexiglass

Product Description

Versatility: Acrylic glass is available in a wide range of thicknesses, sizes, and colors, providing flexibility for different purposes. It can be easily cut, shaped, and molded to fit specific project requirements.

Easy maintenance: Acrylic glass is relatively easy to clean and maintain. It can be wiped with a soft cloth and mild soap or glass cleaner to remove dirt or smudges.

Cost-effective: Acrylic glass is generally more affordable than traditional glass, making it a popular choice for many applications where cost efficiency is important.

Product Parameters

| Product Name | Clear Plexiglass Acrylic Sheet, Transparent Plastic Sheet – “PMMA, Lucite, Acrylite, Perspex, Acrylic, Plexiglas, Optix” |

| Long Name | Polymethyl Methacrylate |

| Material | 100% Virgin PMMA |

| Surface Finish | Glossy |

| Size | 1220*1830mm/1220x2440mm (48*72 in/48*96 in) |

| Thickness | 0.8 0.8- 10 mm ( 0.031 in – 0.393 in) |

| Density | 1.2g/cm3 |

| Opacity | Transparent |

| Light Transmission | 92% |

| Acrylic Type | Extruded |

| MOQ | 50 sheets |

| Delivery Time | 5-10 days after order confirmation |

Product Details

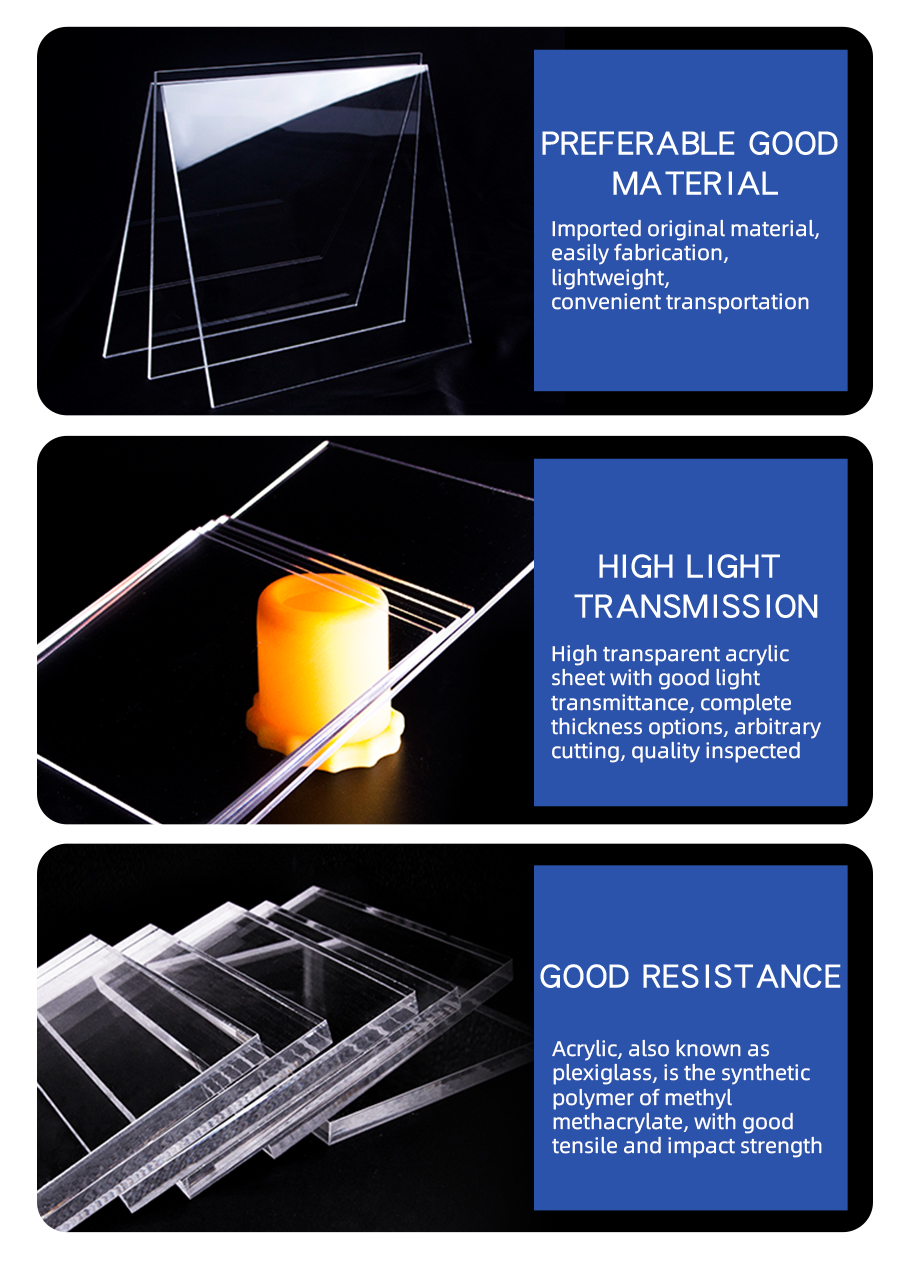

DHUA Acrylic Sheet Is Easily Fabricated

Our versatile acrylic sheet can be easily cut, sawed, drilled, polished, bend, machined, thermoformed and cemented.

Dimension Information

Standard Cut-to-Size length and width tolerances are +/-1/8", but are typically more accurate. Please contact us if you need greater precision. Acrylic sheet thickness tolerances are +/- 10% and can vary throughout the sheet, but variations are typically less than 5%. Please refer to nominal and actual sheet thicknesses below.

- 0.06" = 1.5mm

- 0.08" = 2mm

- 0.098" = 2.5mm

- 1/8" = 3mm = 0.118"

- 3/16" = 4.5mm = 0.177"

- 1/4" = 5.5mm = 0.217"

- 3/8" = 9mm = 0.354"

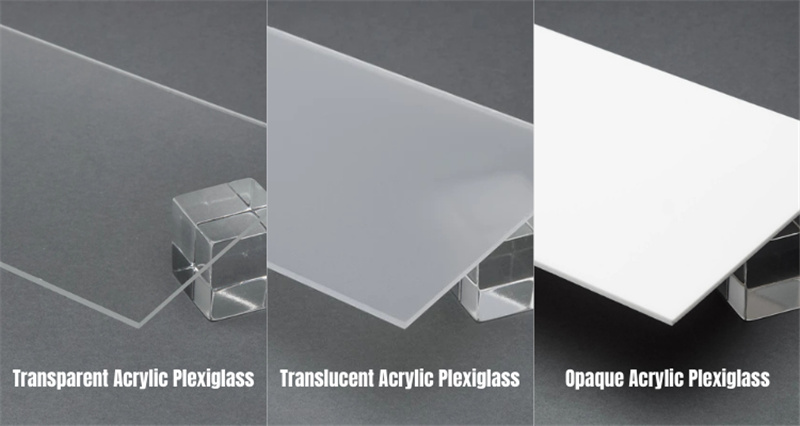

Translucent, Transparent or Opaque Colored Acrylic Plexiglass Avalilable

· Transparent Acrylic Plexiglass = Images can be viewed through sheet (like tinted glass)

· Translucent Acrylic Plexiglass = Light & Shadows can be seen through Sheet.

· Opaque Acrylic Plexiglass = Neither light nor images can be seen through the sheet.

Applications

A versatile and all-purpose acrylic sheet with multi-functional properties, extruded acrylic sheet has s a wide range of applications in many residential, commercial, industrial, and professional uses.

Typical Applications:

Glazing, guards & shields, signs, lighting, picture frame glazing, light guide panel, signage, retail display, advertising and point of purchase & sale displays, trade show booths and display cases, cabinet fronts and a variety of other DIY home projects. The listing that follows is merely a sample.

■ Point-of-purchase displays ■ Trade show exhibits

■ Map/photo covers ■ Framing medium

■ Electronic equipment panels ■ Machine glazing

■ Safety glazing ■ Retail display fixtures and cases

■ Brochure/ad holders ■ Lenses

■ Splash guards ■ Lighting fixture diffusers

■ Signs ■ Transparent equipment

■ Models ■ Sneeze guards

■ Demonstration windows and housings ■ Equipment covers

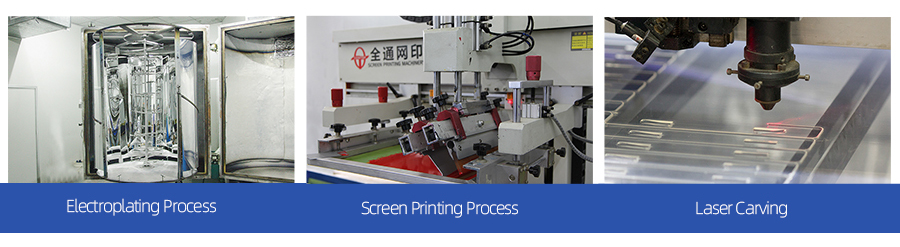

Production Process

Extruded acrylic sheet is produced by an extrusion process. Acrylic resin pellets are heated to a molten mass which is continuously pushed through a die, the position of which determines the thickness of the sheet produced. Once through the die, the molten mass looses temperature and can be trimmed and cut to the required sheet sizes.

Packaging & Shipping

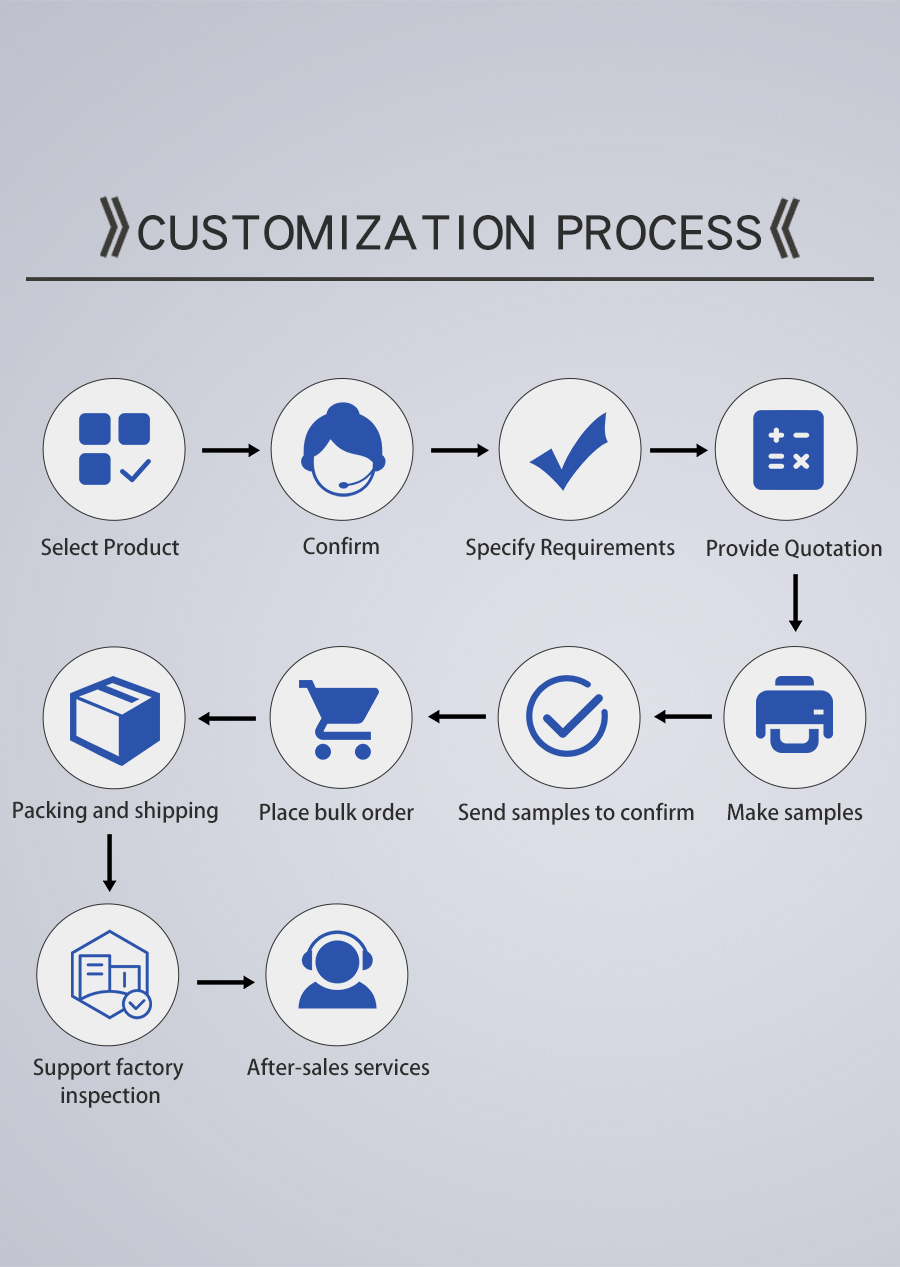

Customization Process

Why Choose Us?

Verified Supplier, Quality Assurance

Strong supply ability: Our factory covering an area of 25000 square meters has a monthly production capacity of 15 million tons, which are exported to more than 80 countries around the world such as Europe, America, Middle East, Australia ect.

Independent R&D: One-stop design and production; Support processing & customization; 1000+ models of independent research and development

Worry-free services: Small business accepted, one-stop shopping and processing service, quality assurance of high quality, quick feedback to any problem, favorable offer of EXW, FOB and CIF. and ensure on-time, in-full delivery