OEM Customized Printed Acrylic Sheet - Clear Transparent Perspex Plexiglass Acrylic Sheet – Donghua

OEM Customized Printed Acrylic Sheet - Clear Transparent Perspex Plexiglass Acrylic Sheet – Donghua Detail:

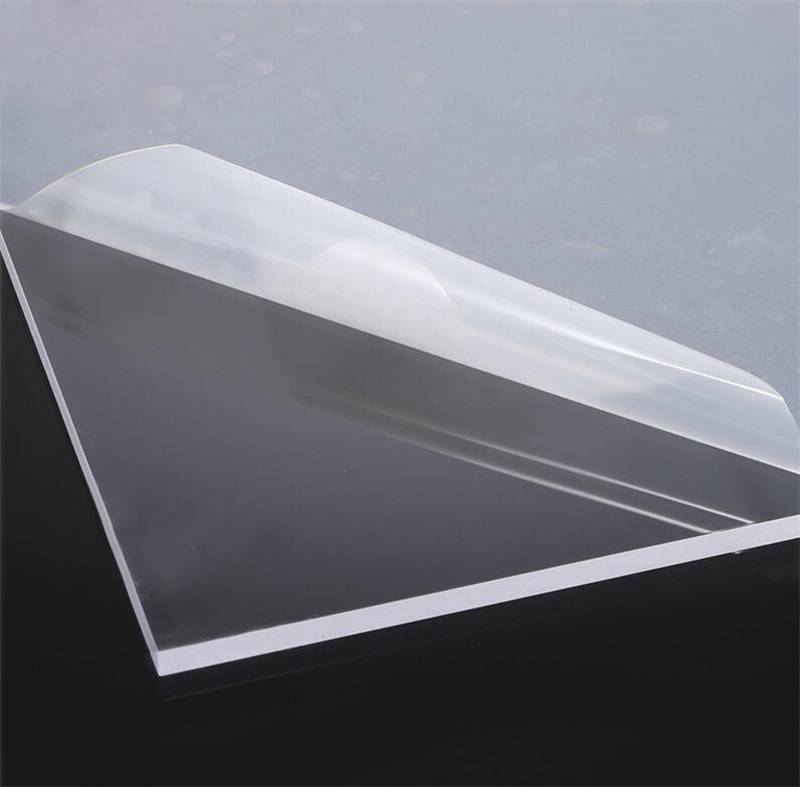

Clear Plexiglass Acrylic Sheet, Transparent Plastic Sheet

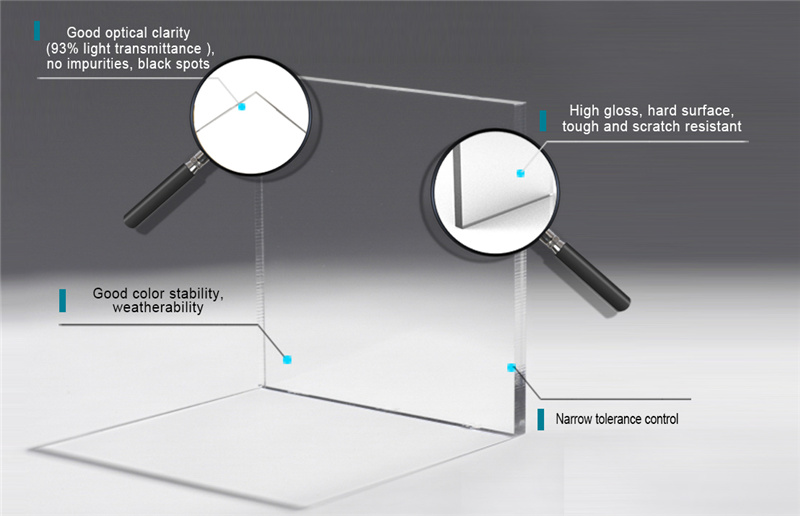

Acrylic, also known as Plexiglass, is thermoplastics and often supplied in sheets as a lightweight or shatter-resistant alternative to glass. Clear Acrylic Sheets exhibit glass-like qualities—clarity, brilliance, and transparency—but at half the weight and many times the impact resistance of glass. It is easy to fabricate, bonds well with adhesives and solvents, and is easy to thermoform without loss of optical clarity.

Donghua mainly provide extruded acrylic sheet available in full sheets, cut-to-size sheets in various sizes, grades, and shapes.

| Product Name | Clear Plexiglass Acrylic Sheet, Transparent Plastic Sheet – “PMMA, Lucite, Acrylite, Perspex, Acrylic, Plexiglas, Optix” |

| Long Name | Polymethyl Methacrylate |

| Material | 100% Virgin PMMA |

| Surface Finish | Glossy |

| Size | 1220*1830mm/1220x2440mm (48*72 in/48*96 in) |

| Thickness | 0.8 0.8- 10 mm ( 0.031 in – 0.393 in) |

| Density | 1.2g/cm3 |

| Opacity | Transparent |

| Light Transmission | 92% |

| Acrylic Type | Extruded |

| MOQ | 50 sheets |

| Delivery Time | 5-10 days after order confirmation |

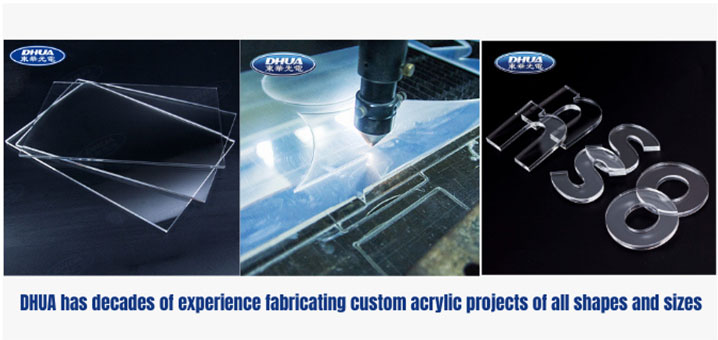

DHUA Acrylic Sheet Is Easily Fabricated

Our versatile acrylic sheet can be easily cut, sawed, drilled, polished, bend, machined, thermoformed and cemented

Dimension Information

Standard Cut-to-Size length and width tolerances are +/-1/8″, but are typically more accurate. Please contact us if you need greater precision. Acrylic sheet thickness tolerances are +/- 10% and can vary throughout the sheet, but variations are typically less than 5%. Please refer to nominal and actual sheet thicknesses below.

- 0.06″ = 1.5mm

- 0.08″ = 2mm

- 0.098″ = 2.5mm

- 1/8″ = 3mm = 0.118″

- 3/16″ = 4.5mm = 0.177″

- 1/4″ = 5.5mm = 0.217″

- 3/8″ = 9mm = 0.354″

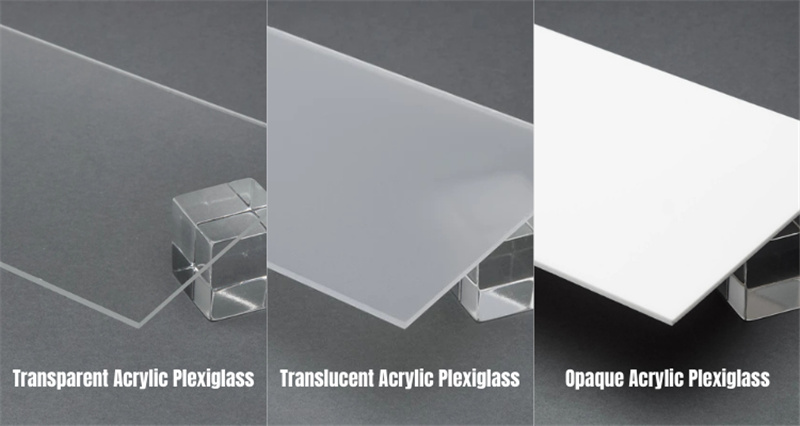

Translucent, Transparent or Opaque Colored Acrylic Plexiglass Avalilable

· Transparent Acrylic Plexiglass = Images can be viewed through sheet (like tinted glass)

· Translucent Acrylic Plexiglass = Light & Shadows can be seen through Sheet.

· Opaque Acrylic Plexiglass = Neither light nor images can be seen through the sheet.

Applications

A versatile and all-purpose acrylic sheet with multi-functional properties, extruded acrylic sheet has s a wide range of applications in many residential, commercial, industrial, and professional uses.

Typical Applications:

Glazing, guards & shields, signs, lighting, picture frame glazing, light guide panel, signage, retail display, advertising and point of purchase & sale displays, trade show booths and display cases, cabinet fronts and a variety of other DIY home projects. The listing that follows is merely a sample.

■ Point-of-purchase displays ■ Trade show exhibits

■ Map/photo covers ■ Framing medium

■ Electronic equipment panels ■ Machine glazing

■ Safety glazing ■ Retail display fixtures and cases

■ Brochure/ad holders ■ Lenses

■ Splash guards ■ Lighting fixture diffusers

■ Signs ■ Transparent equipment

■ Models ■ Sneeze guards

■ Demonstration windows and housings ■ Equipment covers

Production Process

Extruded acrylic sheet is produced by an extrusion process. Acrylic resin pellets are heated to a molten mass which is continuously pushed through a die, the position of which determines the thickness of the sheet produced. Once through the die, the molten mass looses temperature and can be trimmed and cut to the required sheet sizes.

Product detail pictures:

Related Product Guide:

Our firm has been concentrating on brand strategy. Customers' satisfaction is our best advertising. We also offer OEM provider for OEM Customized Printed Acrylic Sheet - Clear Transparent Perspex Plexiglass Acrylic Sheet – Donghua , The product will supply to all over the world, such as: Belarus, Latvia, Hamburg, We have constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Portugal for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.